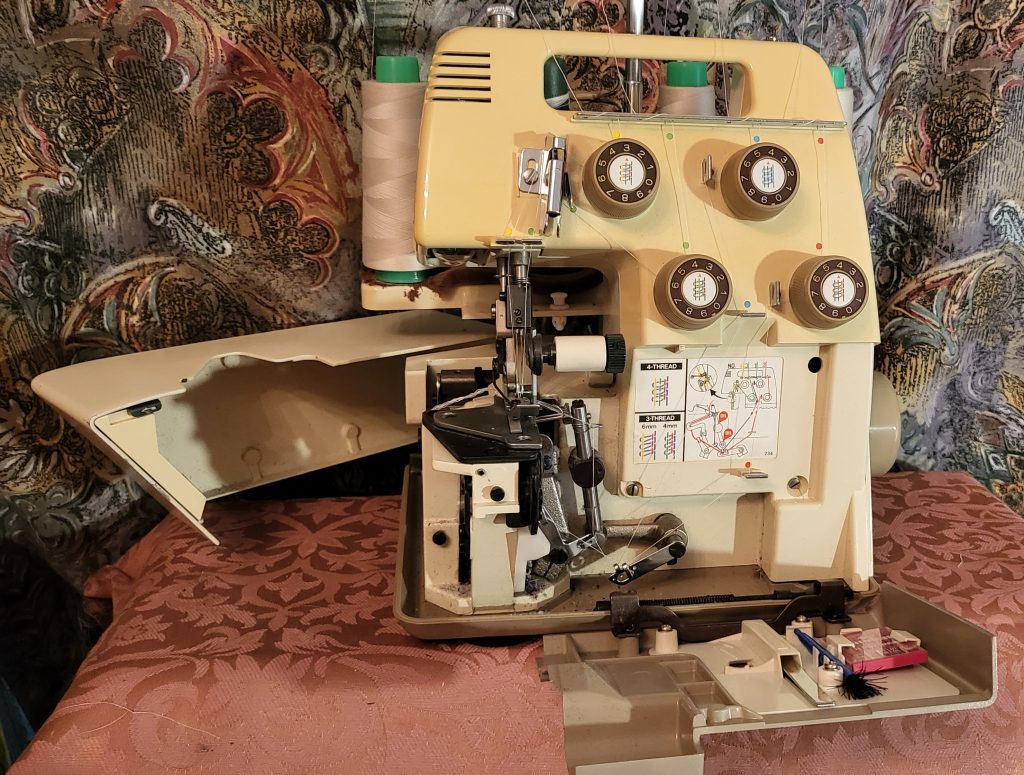

Bernina overlocker / serger

circa mid 1987. 4 thread. Can be 3 thread.

This machine appears to have been released worldwide with the same name, Bernette M0- 234.

A Juki machine made in Japan for Bernina.

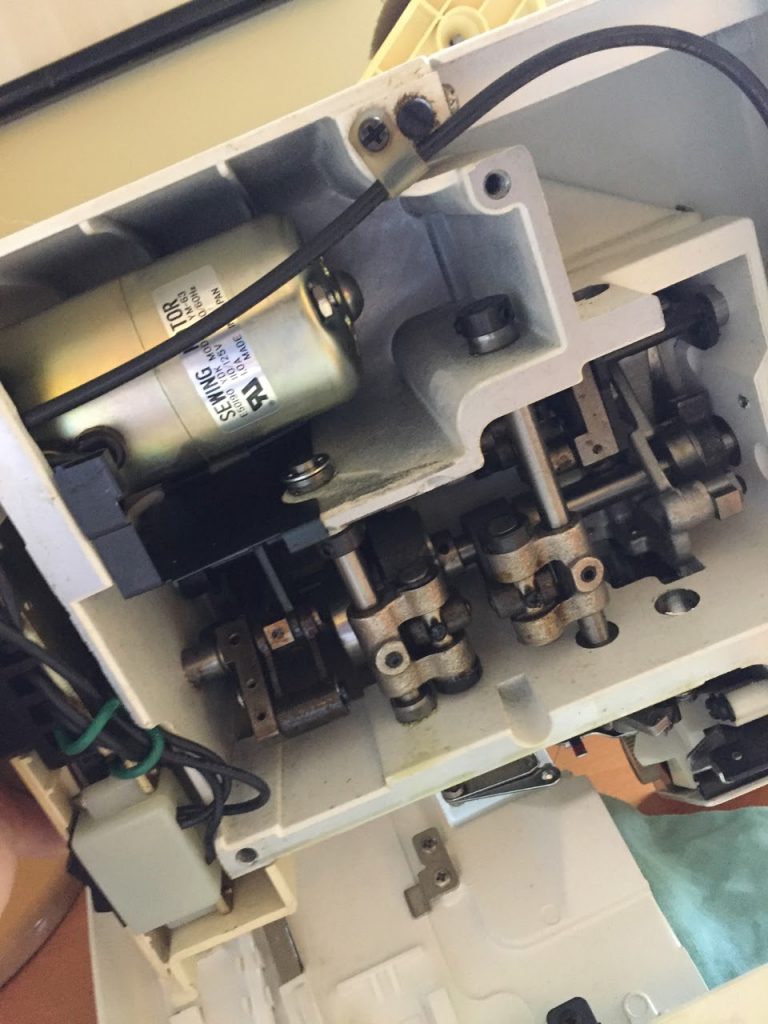

Two internal plastic working parts.

The instruction book that came with this machine is free to download here.

I also now have information and a page on the Bernette 334D.

Saw it..

I spotted this machine advertised on a social media “for sale page”.

I had heard so many good things about this machine and it was the first I had seen advertised locally.

I had read it was all metal and built like a tank. Maybe a plastic tank?

Collected..

Picked it up and started to inspect the machine. Presser foot off, front plate off, shine a torch inside, so far so good. A bit of fluff, but that is normal.

Oh Ohhhh… plastic. NO!!! this machine has two internal brackets/moving parts that are plastic. This is exactly what I did not want to see or expect to see.

Dissapointed..

Don’t get me wrong, the machine works fine. Still! Plastic, no matter how nice it is now, will eventually deteriorate, much faster than steel, so this machine won’t last as long as some of the other early models. With a lot of use, these plastic joints will wear out. With light use they will also deteriorate.

This machine has a lot more plastic on the exterior than many of the other early Japanese machines I have seen. Even the bottom is plastic and broken. The rubber feet are quite thin/ flat and not as sturdy as the other machines.

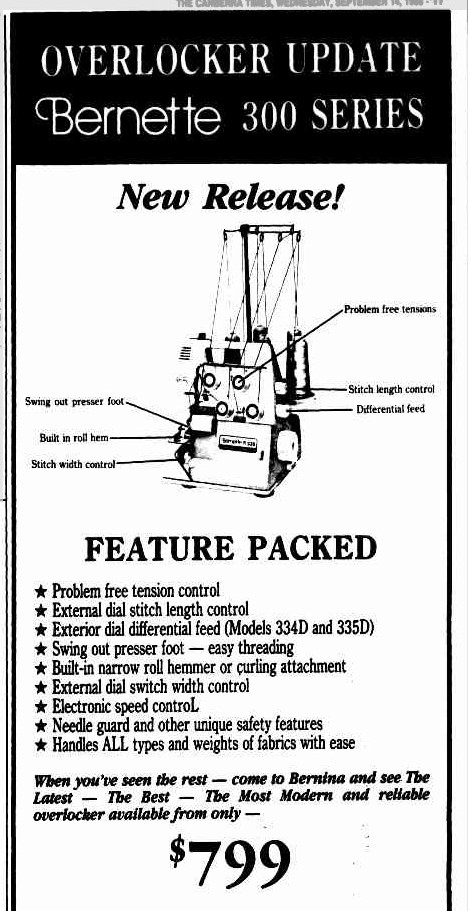

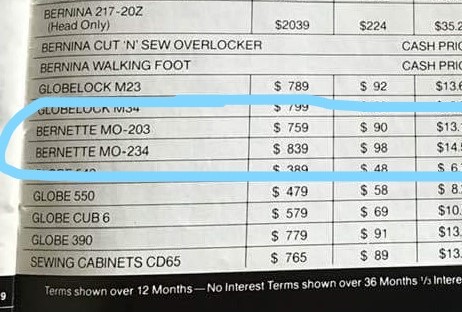

In 1988 this machine was discounted to $799 from $899. Newspaper advertisement at bottom of this page.

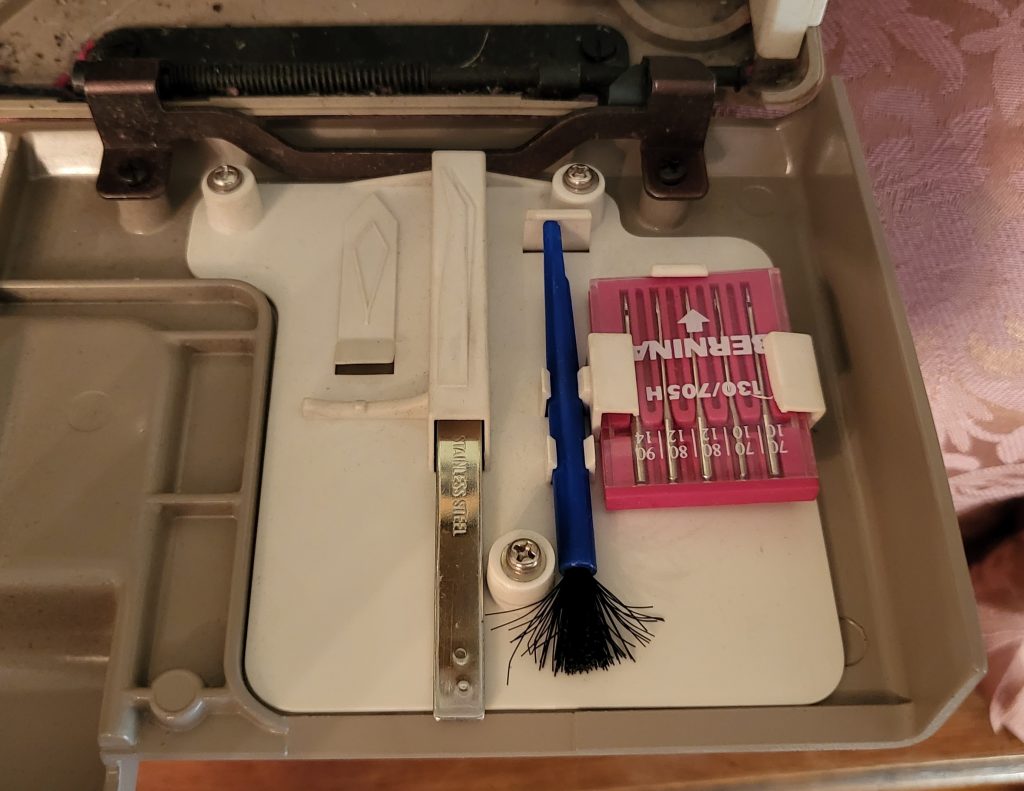

There are a few things I like. It has the accessories behind the front door. The spool pin holder moves across and then back for safe storage. The plastic front plate, right side plate, and plastic spool pin holder are all easy to remove for maintenance.

There are a few things I don’t like. Plastic spool pins, plastic gears, plastic bottom and hard to get at motor for oiling.

Research..

I have found this image on the blogspot, Male Pattern Boldness.

male pattern boldness: Oh, Joy: My First Bernina Serger!

This Bernette is a 334DS, differential feed and it does not look like it has the same plastic parts as my machine.

More research is required. So, for now, I don’t know if all Bernettes are the same.

Is mine a later model? Maybe the earlier releases are all metal and the later have plastic? It is very possible.

Is mine a budget range?

I would love feedback from anyone who has insight into this.

334D update.

I have since found a 334d model, you can see it on the Bernette 334D page. It has a plastic looper drive gear, so again something plastic. I now suspect the 334DS also has the plastic looper drive gear.

Up and running..

Initially I could not get a nice stitch. The machine was cleaned, oiled and running smoothly. I found that I needed to dismantle and clean two of the tension disks. These machines can be rather particular and if the thread is not running smoothly through all thread guides, it can cause all sorts of trouble.

Final stitch. The final stitch is nice and the machine has a lovely solid feel. If I was going to use the machine, I would fine tune the tension. I am just glad that it is working well and has come back to life.

Gallery..

1988

http://nla.gov.au/nla.news-article102070730

Thank you so much for this comprehensive review. ! I just bought s 334 at an suction and you havr given me hope that I can look forward to restoring it

You are welcome. I hope you can get your machine restored and running. Please keep me up to date. I am curious if the 334 has any plastic internal parts.

Thank you for the photos and the information. I was considering purchasing this serger and your information was great! Thanks again and God Bless!

Hello, Thank you for your blogsite. I just purchased a second hand Bernette mo-303 today in order to access the blind hemming and roll hemming facility. The information you have presented is very useful. I purchased my original Bernette mo-203 in the early eighties. I have only used it in its original factory settings all this time and have only recently discovered that it can do more than just overlock. It’s sad to find out about the addition of plastic components in newer models, though. I am also an owner of a Necchi Lydia 3 sewing machine, purchased for me, by my parents when I was in high school. It has served me well all these years and except for the nylon cam shaft (a fatal flaw of this model), though slightly cracked, is still serviceable. I have recently found a beautiful Bernina 830 Electronic Record, lightly used and in beautiful condition(1981). I can see why technicians/engineers love it because it’s made for servicing!

I bought a Bernette MO-234 and I know nothing about sergers except that I wanted one. It is very clean and almost looks like it was never used. It came with all the little tools that also look new including the brush. All the pictures I have seen show a smooth top with the presser foot adjustment screw on the left and a single little screw on the right. However, my machine has a metal thing on the right that looks like a tension adjustment of some sort. I can’t find anything about the use of it. I have seen a couple pictures with one but I am at a loss. Help. Thanks.

Hi Charlena, Unfortunately, I am not a tech and find it difficult to repair sergers/overlockers. You may want to join the Vintage Baby Lock/Juki Sergers & Variants ps://www.facebook.com/groups/760861027876140 page. There you will find other owners and will be able to upload photos to your specific problem/query. Good luck.